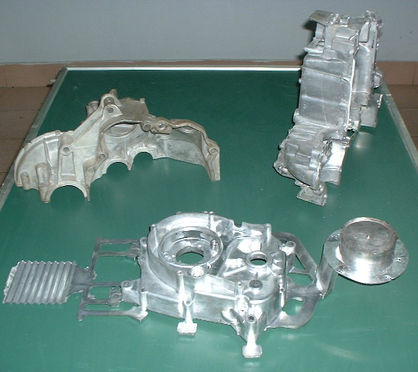

DIE CASTING

At Lentech we manufacture aluminium, brass and zinc, die castings. Our machine ranges from 180 to 1200 tons. The die cast parts are CNC machined. We can supply finished parts that require painting, powder coating, plating, glass bead blast, brush finish to customers requirement. We design and manufacture our die casting tools.

INVESTMENT CASTING

Lentech also supplies investment cast parts Ferrous, Non-Ferrous, all grades of stainless steel, Carbon Steel, Low Alloy, High Alloy, Tool Steels, Iron materials. Castings ranging from as little as a few grams up to 100 kgs in weight. The casting is machined, surface finished if required by glass bead finish, polished and buffed, scotch bright polished on finished products.

We have accomplished architectural projects where stainless-steel parts were cast, welded together, surface finished by glass bead blasting or using scotch bright polishing pads for dull smooth- sun ray finished.

The following are some of the materials we are able to work with:

Stainless Steels – Heat and Corrosion Grades, Steels – Carbon, Low Alloy, High Alloy, Tool Steels, Iron – Grey, Ductile Irons, Non-Ferrous – Copper, Brass, Bronzes, Aluminium.

SAND AND SHELL MOULD CASTING

We supply gear boxes housings, pump housings, drainage lids, gas cover & lids, valve handles and many more parts made of SG iron, grey iron, ductile iron castings.

If you have any casting requirements please contact our team at info@lentechind.com or contact us using the form on this website or call us at +91 9036 224 236 or 8861 643 236 for a fast quote and advice.